Aircraft, satellites, and military equipment require precise components to ensure safety, performance, and adherence to strict regulations.

Precision machining is crucial in the aerospace industry because aircraft and spacecraft components must meet extremely tight tolerances to ensure safety, performance, and reliability. Here’s how it plays a vital role:

- Material Selection: Aerospace parts are often made from high-strength materials like titanium, aluminum, and advanced composites that require precision machining techniques.

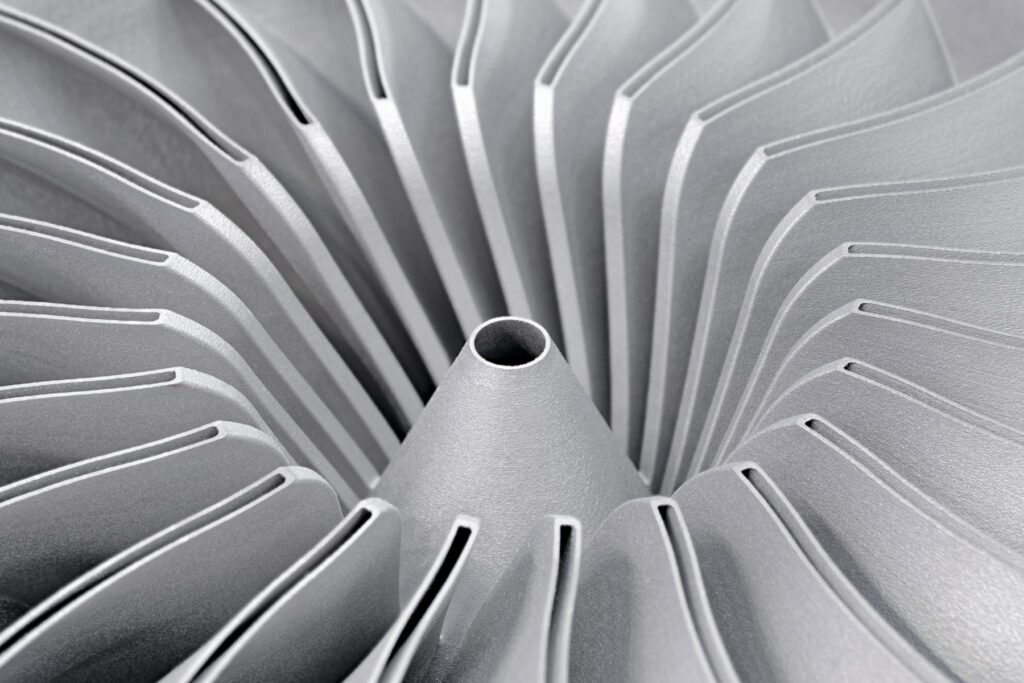

- Complex Geometries: Components such as turbine blades, engine housings, landing gear parts, and structural elements need to be machined with extreme accuracy to fit seamlessly.

- Strict Regulations: The aerospace industry enforces rigorous quality and safety standards, requiring manufacturers to use advanced machining processes for compliance.

- Weight Reduction: Precision machining helps create lightweight but strong components, which is essential for improving fuel efficiency and aircraft performance.

- Advanced Technologies: CNC machining, multi-axis milling, and EDM (electrical discharge machining) allow for the production of intricate parts with minimal error.

- High Reliability: Aerospace components must endure extreme temperatures, pressures, and forces, so precision machining ensures durability and consistent functionality.